The Trim Guide Tool is an essential instrument for precise cutting and alignment in various projects, ensuring accuracy and efficiency in handling materials like wood, metal, and plastic.

Overview of the Trim Guide Tool

The Trim Guide Tool is a versatile and practical instrument designed to enhance precision and efficiency in cutting and trimming tasks. It is widely used in woodworking, metalworking, and crafting projects, offering a reliable way to achieve clean, accurate cuts. The tool’s compact design and user-friendly interface make it accessible for both professionals and hobbyists. Its primary function is to guide the cutting tool or blade along a predetermined path, ensuring consistent results. This tool is particularly valuable for intricate designs and repetitive tasks, where accuracy is paramount.

Importance and Applications

The Trim Guide Tool is indispensable for achieving precision and efficiency in various tasks. It minimizes material waste and ensures clean, professional results. Widely used in woodworking, metalworking, and crafting, the tool excels in cutting, trimming, and aligning materials. Its applications extend to DIY projects, furniture making, and industrial settings, where accuracy is critical. By streamlining workflows, it saves time and enhances productivity, making it a valuable asset for both professionals and hobbyists seeking consistent, high-quality outcomes.

Key Features and Components

The Trim Guide Tool features an adjustable design, durable construction, and precise alignment capabilities. It includes customizable settings and interchangeable accessories for versatility in various cutting tasks.

Design and Functionality

The Trim Guide Tool is crafted with an ergonomic design for comfortable handling and precision. Its durable construction ensures longevity, while its adjustable features allow for customizable alignment. The tool’s functionality revolves around facilitating accurate cuts and smooth material handling. It often includes measurement markers and a secure clamping system to maintain stability during use. This design ensures consistency and efficiency, making it a reliable choice for professionals and DIY enthusiasts alike.

Customization Options

The Trim Guide Tool offers extensive customization options, allowing users to tailor its functionality to specific tasks. Adjustable measurement guides and interchangeable cutting edges enable precise adaptations for various materials. Users can also modify the tool’s alignment settings to suit different project requirements. Additionally, compatibility with aftermarket accessories provides further flexibility. These customization features ensure the tool can be optimized for individual workflows, enhancing productivity and versatility across a wide range of applications;

Compatibility with Various Tools

The Trim Guide Tool is designed to work seamlessly with a variety of tools and equipment, enhancing its versatility in different workflows. It integrates effortlessly with power tools, precision instruments, and software solutions, making it a valuable asset for professionals and DIY enthusiasts alike. This compatibility ensures that users can leverage the tool’s functionality across multiple projects and industries, streamlining processes and improving overall efficiency. Its adaptability makes it a reliable choice for both traditional and modern applications.

Selecting the Right Trim Guide Tool

Choosing the right trim guide tool involves considering project size, material type, and specific features to ensure precision and efficiency in your tasks.

Factors to Consider

When selecting a trim guide tool, consider the type of material, project size, and desired precision. Ensure compatibility with your existing tools and workspace. Ergonomics and durability are crucial for long-term use. Assess the tool’s adjustability and ease of calibration. Budget and brand reputation also play significant roles in making the right choice. Aligning these factors with your specific needs ensures optimal performance and satisfaction in your projects.

Project-Specific Requirements

Project-specific requirements dictate the trim guide tool’s adaptability to unique demands. Consider the material type, precision level, and project size. Adjustable guides and compatibility with various tools enhance versatility. Ensure the tool aligns with the task’s complexity, whether for woodworking, metalwork, or plastics. Ease of calibration and portability are key for on-site adjustments. Matching the tool to the project’s scope ensures efficiency and delivers professional-grade results, making it an indispensable asset for tailored applications.

Using the Trim Guide Tool

The Trim Guide Tool simplifies precise cutting and alignment, ensuring accuracy and efficiency. Align materials, adjust settings, and maintain safety for optimal results in woodworking, metalwork, or plastics.

Step-by-Step Guide

Start by preparing the Trim Guide Tool, ensuring all components are securely attached. Align the tool with your material, adjusting the guide to match your desired measurements. Clamp the material firmly and double-check the alignment for accuracy. Begin trimming slowly, maintaining steady pressure to avoid uneven cuts. Use safety gloves and goggles to protect yourself. After completing the trim, inspect the edge for smoothness and make minor adjustments if needed. Store the tool properly to maintain its precision and longevity.

Best Practices for Efficiency

For optimal efficiency with the Trim Guide Tool, always ensure proper alignment and secure clamping of materials before cutting. Regularly clean and lubricate moving parts to maintain smooth operation. Use high-quality blades to minimize wear and tear. Prior to trimming, double-check measurements to avoid waste. Store the tool in a dry, protected area to prevent rust and damage. Practice safety by wearing protective gear and keeping loose clothing tied back. Organize materials beforehand to streamline the trimming process and achieve professional-grade results consistently.

Maintenance and Care

Regular maintenance ensures the trim guide tool’s longevity and optimal performance. Clean the tool after each use, store it in a dry place, and lubricate moving parts regularly. Inspect for damage and replace worn components promptly to maintain accuracy and functionality.

Cleaning and Storage Tips

Regular cleaning and proper storage are crucial for maintaining the trim guide tool’s performance. Use a soft cloth to wipe away debris and avoid harsh chemicals that may damage the surface. Store the tool in a dry, cool place to prevent rust or corrosion. For tools with moving parts, apply a light layer of lubricant to ensure smooth operation. Always inspect for damage before storing and consider using a protective case to extend the tool’s lifespan and maintain its accuracy.

Troubleshooting Common Issues

Common issues with the trim guide tool include misalignment, wear, and difficulty in achieving straight cuts. To resolve these, ensure the tool is properly calibrated and free from debris. Lubricate moving parts if they stick, and inspect for damage regularly. If cuts are uneven, check the blade or cutting surface for dullness or improper alignment. Recalibrate the tool according to the manufacturer’s instructions for optimal performance. Addressing these issues promptly ensures accuracy and extends the tool’s lifespan, maintaining efficiency in your projects.

Safety Guidelines

Always wear safety goggles and gloves when using the trim guide tool. Ensure it is well-maintained and follow proper handling techniques to prevent injuries.

Precautions and Safety Measures

When using the trim guide tool, always wear protective gear like safety goggles and gloves to prevent injuries. Ensure the tool is in good condition and properly aligned before use. Avoid wearing loose clothing that could get caught in moving parts. Keep the work area clean and well-lit to maintain visibility. Follow the manufacturer’s guidelines and safety protocols strictly. Never operate the tool near flammable materials or in hazardous environments. Regular maintenance and proper storage are crucial to ensure safe and efficient performance.

Remember: Safety should always be the top priority to avoid accidents and ensure optimal results.

Advanced Techniques

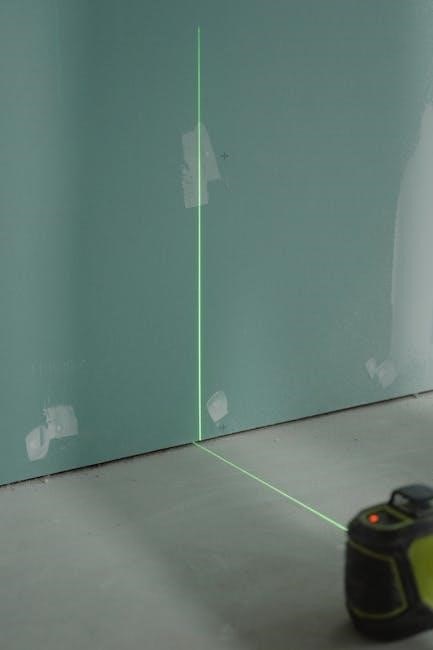

Advanced techniques with the trim guide tool involve specialized applications, such as intricate cuts and precision alignments, often integrated with AI tools for enhanced accuracy and efficiency.

Specialized Applications

The trim guide tool excels in specialized applications, such as precision cutting for intricate designs, aligning materials in tight spaces, and integrating with AI tools for enhanced accuracy. Its versatility allows for efficient handling of various materials, including wood, metal, and plastic, making it indispensable in both DIY projects and professional settings. Advanced techniques enable users to achieve complex cuts and alignments with minimal effort, ensuring high-quality results in specialized tasks.

The Trim Guide Tool is an indispensable asset for precise cutting and alignment, offering unmatched efficiency and versatility across various materials and projects.

Final Thoughts and Value

The Trim Guide Tool is an indispensable asset for any project requiring precision and efficiency. Its ability to enhance accuracy and streamline workflows makes it a valuable addition to any toolkit. By reducing errors and saving time, it proves to be a cost-effective solution for professionals and DIY enthusiasts alike. Its versatility across materials and applications solidifies its role as a essential tool for achieving professional-grade results in various industries and personal projects.